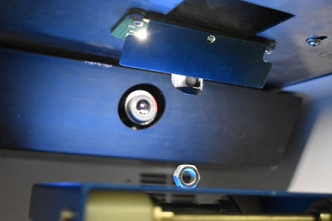

X-Ray Tube

Our X-Ray tubes are known for their performance and long life, making our XRF Machine an ideal solution for demanding applications for those requiring continuous operation.

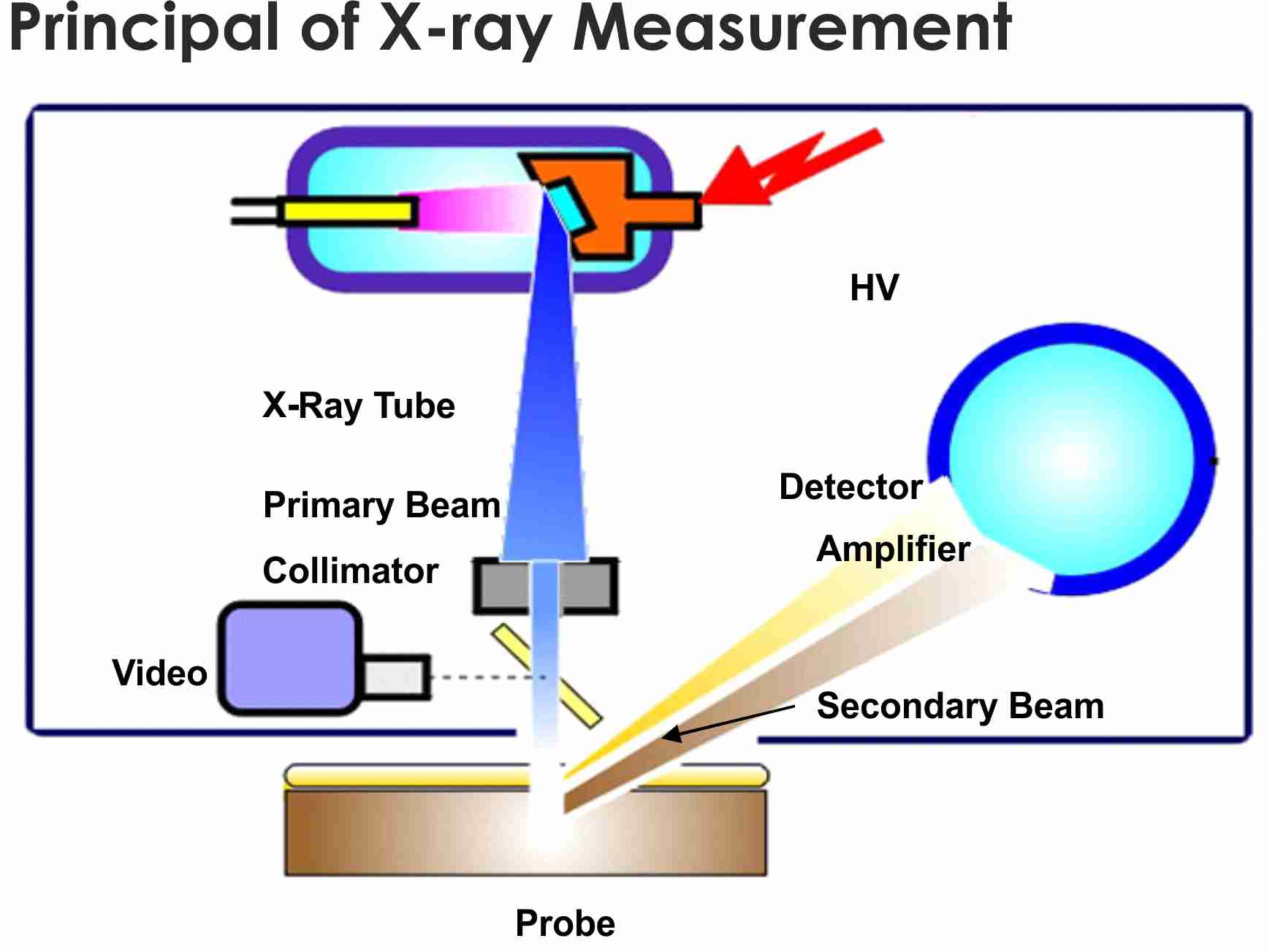

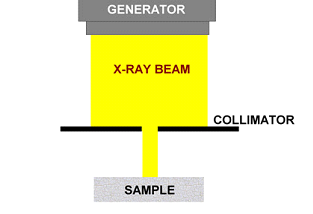

Collimators

A collimator is a device that narrows a beam of particles or waves. Narrow means to cause the directions of motion to become more aligned in a specific direction Cube has collimator options from 0.3 to 0.5 mmØ for generating narrow X-Ray beams for better accuracy and results.

Radiation Protected Glass

CUBE’s apparatus has been designed and tested in accordance with conditions of full protected instruments. In a distance of 5cm from the surface of cabinet system following the Dose was measured: < 1μSV Safety electronic and door/ housing switches switch off High voltages and X-Ray

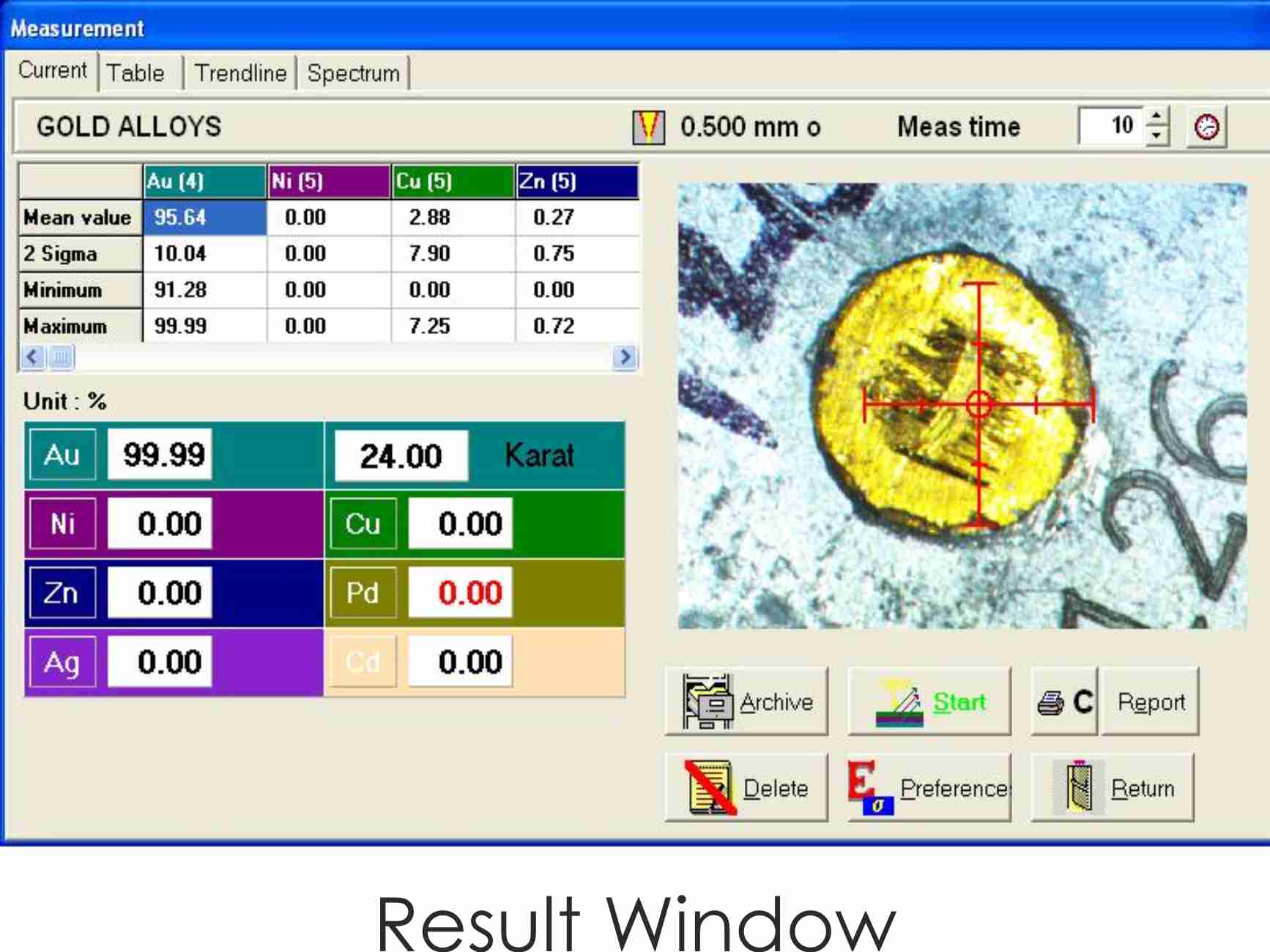

| Cube | Detector | Measuring Direction | Applied Application | X-ray Tube | High Voltage |

|

Gas Filed Prop Counter | Top to Bottom | Gold and Silver Analysis in jewellery and alloys, Coating Thickness Measurements on Metals | Mini-focus,high performance,W-target, Spot 0.2mm-0.8mm, Long Life, High efficiency, tungsten target oil cooled | 0 - 50kV (1.2mA) Software Control Optimized |

| Get A Quote

Full Specs

|

|||||

| Detector | Gas Filed Prop Counter | Measuring Direction | Top to Bottom |

| Applied Application | Gold and Silver Analysis in jewellery and alloys, Coating Thickness Measurements on Metals | X-ray Tube | Mini-focus,high performance,W-target, Spot 0.2mm-0.8mm, Long Life, High efficiency, tungsten target oil cooled |

| High Voltage | 0 - 50kV (1.2mA) Software Control Optimized | Measurement Time | 30 to 60 seconds |

| Collimator | 0.3mmØ or 0.5mmØ, Optional four positions Collimator changer | Dimension (WxDxH) | 350 x 450 x 310 mm (WxDxH) |

| Weight | 27 kg |

| Cube Pin | Detector | Measuring Direction | Applied Application | X-ray Tube | High Voltage |

|

High Resolution SI-PIN | Top to Bottom | Gold and Silver Analysis in jewellery and alloys, Coating Thickness Measurements on Metals | Mini-focus,high performance,W-target, Spot 0.2mm-0.8mm, Long Life, High efficiency, tungsten target oil cooled | 0 - 50kV (1.2mA) Software Control Optimized |

| Get A Quote

Full Specs

|

|||||

| Detector | High Resolution SI-PIN | Measuring Direction | Top to Bottom |

| Applied Application | Gold and Silver Analysis in jewellery and alloys, Coating Thickness Measurements on Metals | X-ray Tube | Mini-focus,high performance,W-target, Spot 0.2mm-0.8mm, Long Life, High efficiency, tungsten target oil cooled |

| High Voltage | 0 - 50kV (1.2mA) Software Control Optimized | Collimator | 0.3mmØ or 0.5mmØ, Optional four positions Collimator changer |

| Dimension (WxDxH) | 350 x 450 x 310 mm (WxDxH) | Measurement Time | 30 to 60 seconds |

| Weight | 27 kg |

| Cube SDD | Detector | Measuring Direction | Applied Application | X-ray Tube | High Voltage |

_02.jpg)

|

Silicon Drift Detector (SDD) | Top to Bottom | Gold and Silver Analysis in jewellery and alloys, Coating Thickness Measurements on Metals | Mini-focus,high performance,W-target, Spot 0.2mm-0.8mm, Long Life, High efficiency, tungsten target oil cooled | 0 - 50kV (1.2mA) Software Control Optimized |

| Get A Quote

Full Specs

|

|||||

| Detector | Silicon Drift Detector (SDD) | Measuring Direction | Top to Bottom |

| Applied Application | Gold and Silver Analysis in jewellery and alloys, Coating Thickness Measurements on Metals | X-ray Tube | Mini-focus,high performance,W-target, Spot 0.2mm-0.8mm, Long Life, High efficiency, tungsten target oil cooled |

| High Voltage | 0 - 50kV (1.2mA) Software Control Optimized | Collimator | 0.3mmØ or 0.5mmØ, Optional four positions Collimator changer |

| Dimension (WxDxH) | 350 x 450 x 310 mm (WxDxH) | Measurement Time | 30 to 60 seconds |

| Weight | 27 kg |