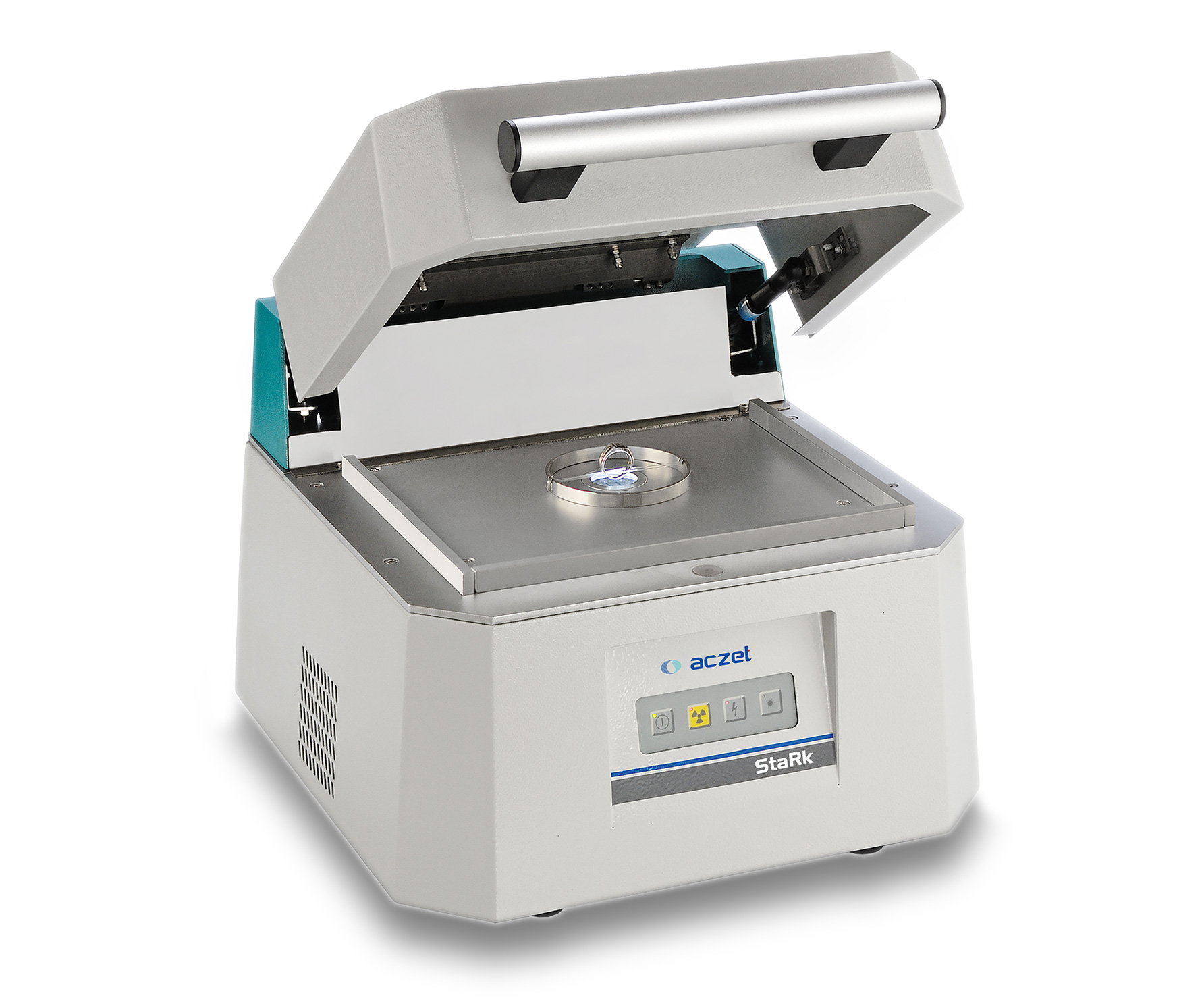

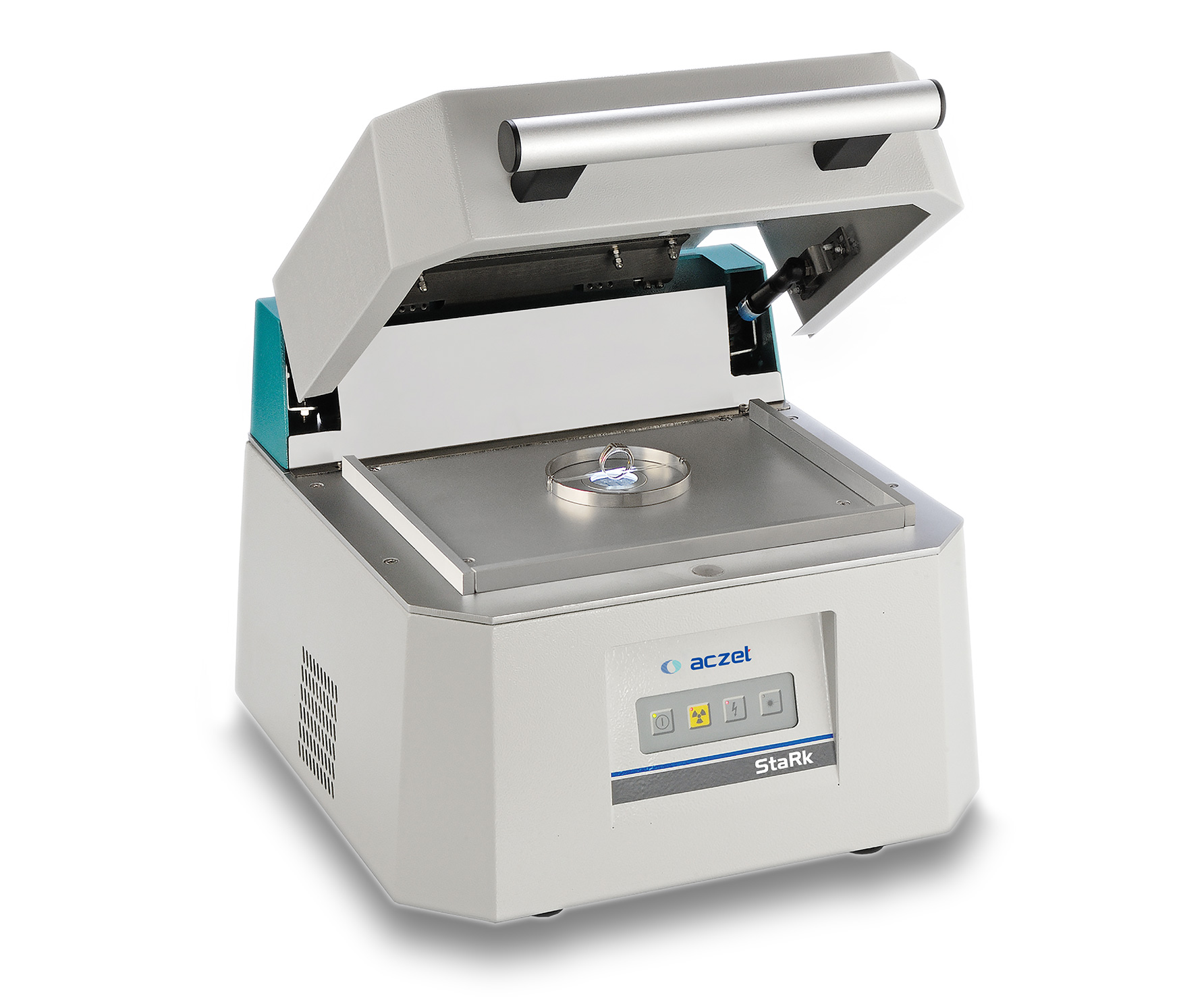

Product

Bottom to Top:

The development of benchtop XRF instruments has greatly expanded the range of samples suitable for analysis. The Bottom to Top XRAY helps in direct exposure of rays on the samples, thus making easy positioning of samples.

Auto Focus:

Being Auto Focus StarK XRF makes it simple and fast for sample positioning, which helps in saving time for those requiring continuous operation.

X-Ray Tube:

StarK family is available in several versions that differ about X-ray tubes, detectors. An option of Proportional counter tube, silicon PIN diode, or Silicon drift detector as X-ray detector is offer in StarK Series. Our X-ray tubes are known for their performance and long life, making our XRF Machine an ideal solution for demanding applications for those requiring continuous operation.

Secure Non Editable Software:

XMaster software is user friendly and easy to use with non-editable results. XMaster is the heart of all Aczet’s X-RAY instruments, enabling the collection of information regarding precious metals, coating thickness, and material analysis. XMaster has both Empirical and Fundamental methods of measurement.

XMaster has eased for the creation of a required application for coating thickness.

Software:

XMasteR Application

X-MasteR is the user-friendly operating software for the modern suit of X-ray systems. This program used the most advanced software tools available for Windows operating platforms. The main task of the operating software is the control of all system parameters such as high voltage settings, X-ray tube current, display of collimators and filters, as well as the collection of the measurement data.

Capability:

· Empirical calibration mode for calibrating unit using well assessed standard samples.

· Fundamental calibration mode for standard free calibrations.

· Simultaneous quantitative measurement of up to 8 elements.

· Qualitative material identification up to 20 elements.

· Spectrum analysis for semi-quantitative concentration measurement.

· Statistical functions with mean value, standard deviation, high/low reading, trend line, etc.

Calibration:

· Pre-calibrated for Gold and other precious metals.