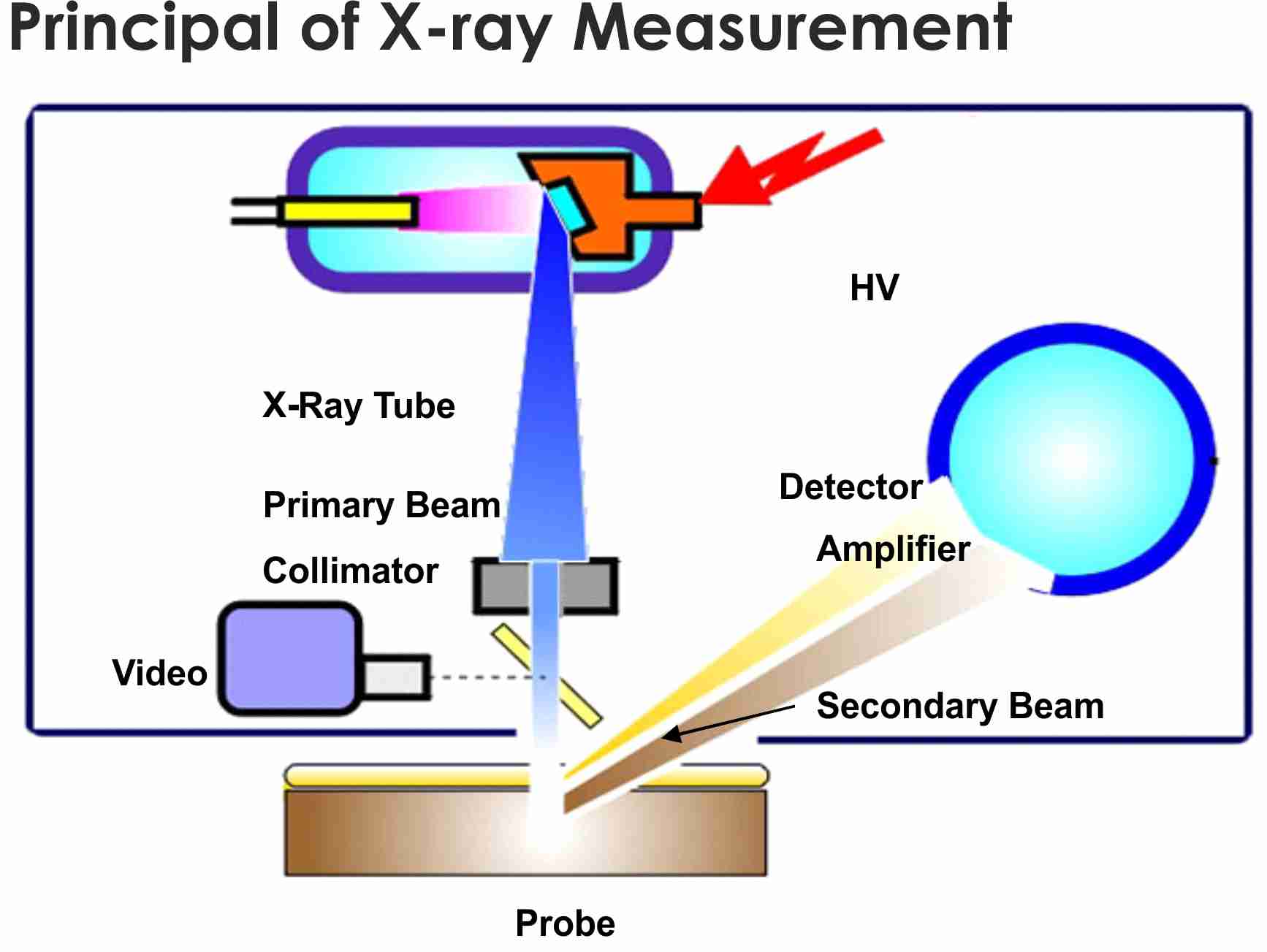

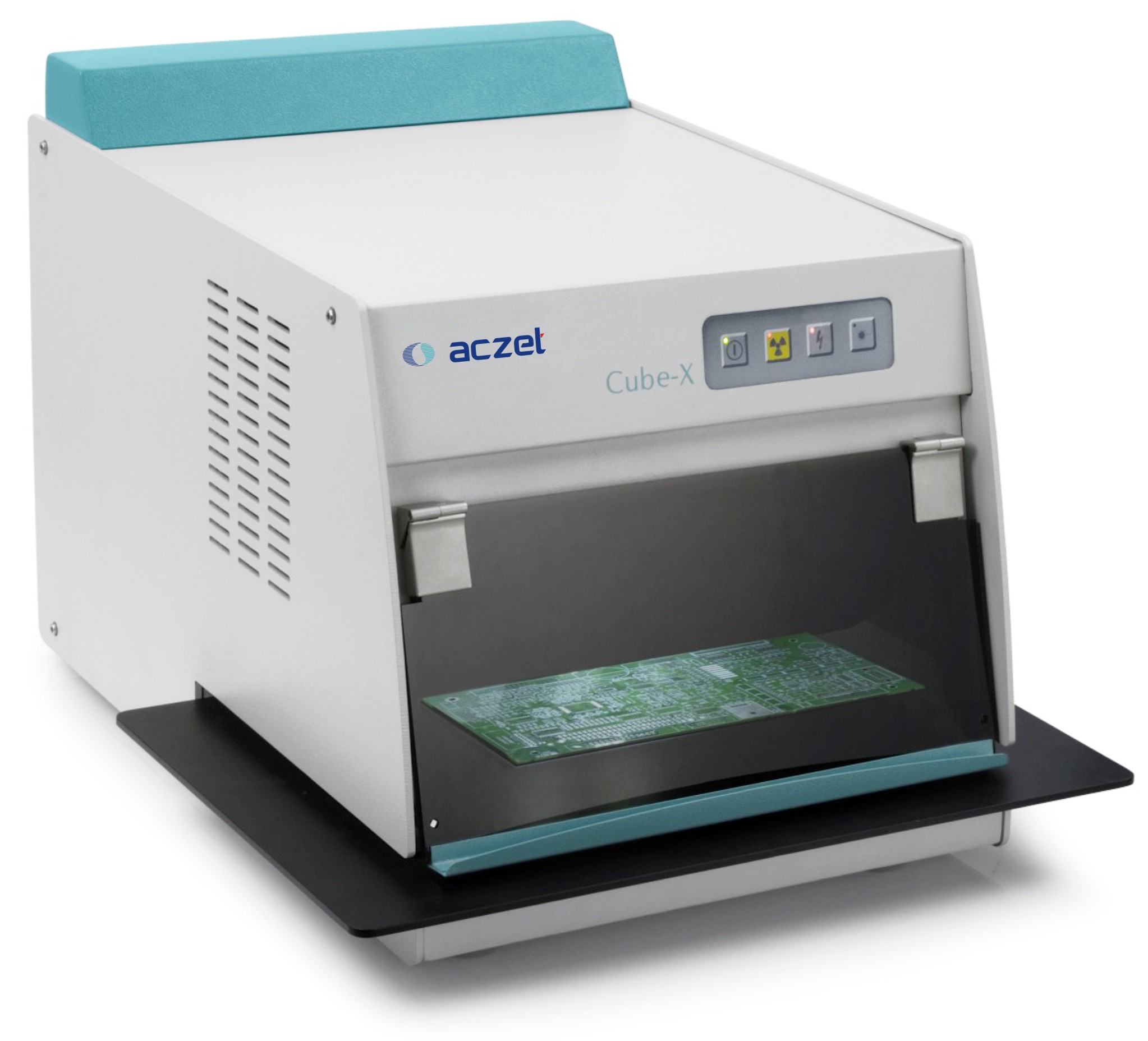

Technology

Proportional Counter, Silicon Pin Detector, and Silicon Drift Detector are the solutions offered on Aczet’s XRF Products.

Proportional Counter Detector

Based on Gas-filled prop counter for measuring the most common alloys, including gold for the jewellery industry. Gas-filled Proportional counter has distinct advantages like high efficiency, wide bandwidth larger area where it can be scaled to almost arbitrarily large size.

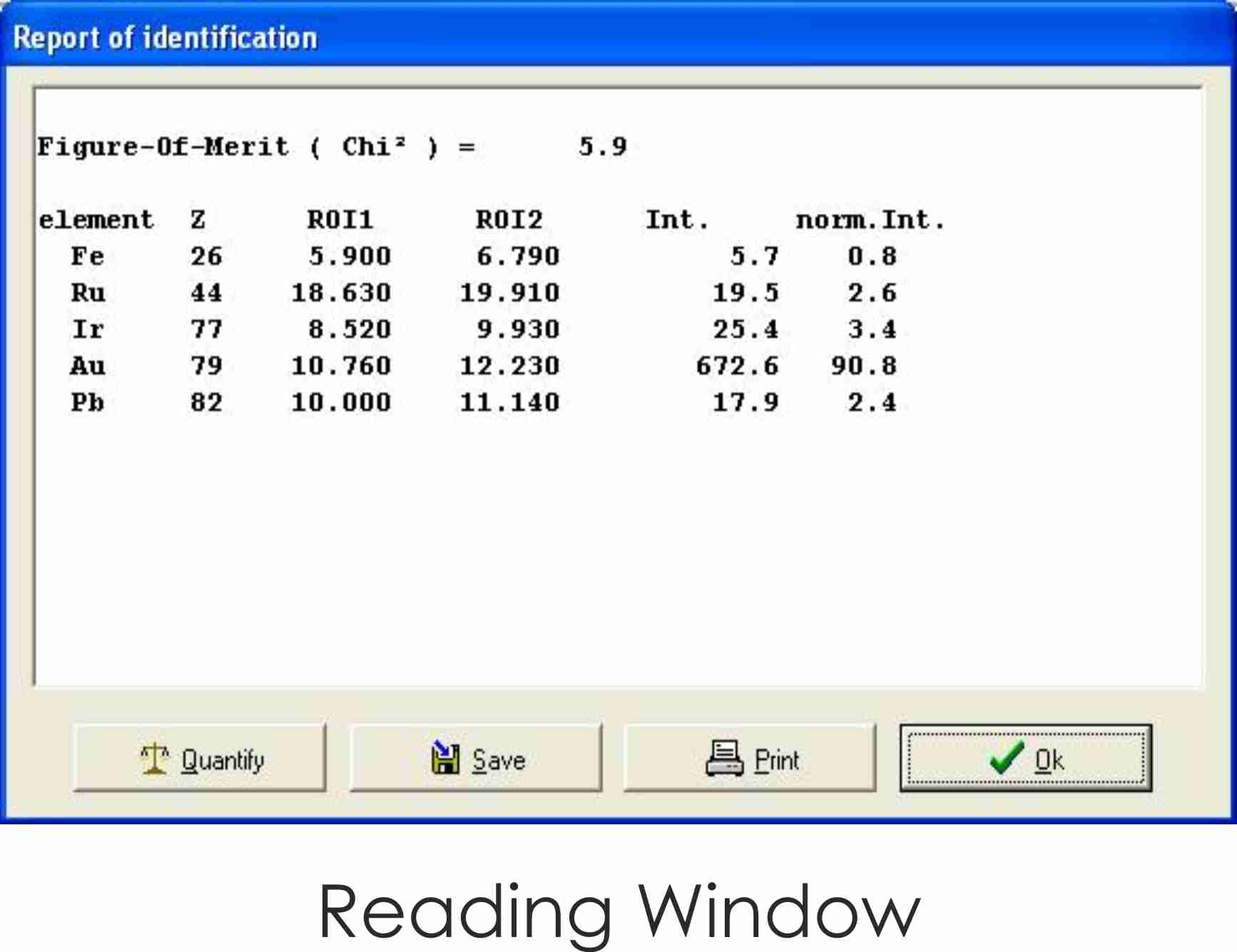

Silicon Detector (Si-PIN )

Based on high-resolution Si-PIN is used for alloys analyzing in jewellery industry, including gold & silver, even one step ahead for accuracy & repeatability compare to Gas-filled pro counter. Si-PIN, with the usage of a high-resolution silicon detector in conjunction with digital signal processing, achieves the best detection limits and highest precision. Based on that, about four times better resolution (in comparison with conventional technique), the element separation is much better. Furthermore, lowest detection limits are achieved because of better signal to noise ratio. The Si-PIN is available with a larger active area and thicker depletion depth. Where resolution is not critical, but high detection efficiency is important, the Si-PIN is the best choice.

Silicon Drift Detector (SDD)

Based on high-resolution SDD, which is ultimate for alloys analyzing an industry, it’s high resolution helps better repeatability and accuracy of the measurement. SDD has better energy resolution than a Si-PIN of the Same area. The SDD has much better energy resolution at short peaking times, which is particularly helpful at high count rates. At the noise corner (the peaking time where the noise is minimal), the SDD’s resolution is still better. So where the highest resolution is needed, or where good resolution is needed at high count rates, the SDD is the choice.